What is a Generator Set? Discover the genset and how it works!

What is a Generating set?

A Generating set (GENSET) is the combination of an internal combustion engine and an electrical generator (alternator) mounted together to form a single piece of equipment. It is an electromechanical machine used to produce an AC electrical current from the thermal energy of combustion by means of a double-cascade converter: from thermal energy (introduced by diesel fuel) to mechanical energy by means of reciprocating motion (engine rotation) and from mechanical energy to electric energy (rotation of the alternator).

Key Components

| 1: Engine | 4: Radiator | 7: Canopy |

| 2: Alternator | 5: Baseframe | 8: Muffler |

| 3: Control Panel | 6: Protection grills | 9: Emergency STOP |

How does it work?

The engine ignites the combustion of diesel fuel, generating mechanical motion. This is transferred to the alternator, which in turn converts it into electrical energy, ready to be used or safely stored.

Genset operating modes

1- Island mode operation

In this example, the GENSET is the only source of energy for the user system. The scope of supply is any location where there is no public distribution network or where the user has decided to directly produce the energy required for their own needs and, if applicable, exploiting the heat emitted by the generator. Typical examples are self-powered equipment and those used on work sites.

2- Genset operation during a power cut to the distribution network

In this example, the user system is normally supplied by the distribution network however, to limit any problems, or material and financial damage, caused by a black-out (data processing centres, hospitals, industrial facilities, etc. operating 24/7), GENSETS, which activate automatically in the event of a power cut to the distribution network, are used. The GENSET is electrically connected to an Automatic Transfer Switch (ATS) panel which automatically switches available power supply sources (GENSET or network) according to the logic controller settings. Depending on the type of control panel assembled on the GENSET, this can operate a short parallel cycle with the network upon its return, so as to eliminate the possible recurrence of a blackout.

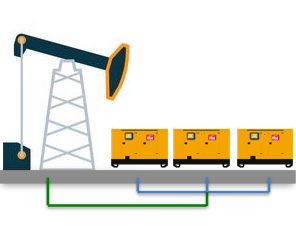

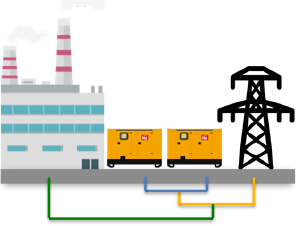

3- Parallel mode operation

- Parallel mode between GENSETS in ISLAND MODE OPERATION: In this example, as well, GENSETS are the only source of energy for the user system, but several GENSETS are used in parallel. This solution is usually determined by the following factors: -continuity of service – continuity of service must be ensured by system redundancy of the component parts (if one GENSET fails or maintenance is being carried out on a GENSET, the load is still partially or totally guaranteed); -the load to be supplied requires more power than can be achieved by a single unit. -consumption optimisation – the load to be supplied varies, with a significant difference between average and peak loads, for which it is recommended to use 2 or more smaller GENSETS in parallel to handle the absorption of peaks though they can normally operate alternately. It is also possible to use several GENSETS in parallel mode and as an emergency backup (without operating in parallel with the network) for the factors outlined above.

- Parallel mode WITH THE NETWORK (long term or temporary): In this example, the GENSETS can operate in parallel mode with one another and with the distribution network; This arrangement is typically used to compensate for absorption peaks not supported by the network or to achieve energy exchanges with the network distributor, in the case of self-powered units. In accordance with the configurations described above, the unit will assume different specifications.

Generating set performance classes

Generating set performance classes are defined in ISO8528. In addition to the basic machine and manufacturer data, in order to comply with the above standard, each GENSET must have a rating plate which lists both the electrical and mechanical quantities, as well as the ambient reference parameters.

Basic electrical quantities of the GENSET: Current and voltage

- Electric current is measured in Amperes [A] and represents, in physics and electrical engineering, the electric charge passing through a cross-section of wire in a unit of time. Electric current can be either direct or alternating. Gensets normally produce alternating current.

- Electric voltage is measured in Volts [V] and the difference in electric potential between two points. Voltage is generated by charge separation and it is the electromotive force which generates the current.

- Electric power is measured in Watts [W] and is defined as the electrical work carried out on an electric load by an electric field within a unit of time; simplification is provided by multiplying current X voltage, or rather P=I*V

Basic electrical quantities of the GENSET: production system

- Electricity can be generated by either a three-phase system or single-phase system. In electrical engineering, the single-phase system is a system for the distribution of electricity. Usually, it is the least complicated system for the distribution of alternating current as it consists of just two conductors, one conventional neutral conductor with zero potential and an active phase conductor with variable potential over time with sinusoidal trend.

- In electrical engineering, the term ‘three-phase system’ refers to a 3 circuit alternating current (the production, distribution and use of electricity) having the same frequency (ISO frequencies) and three equal, alternating voltages, though offset by 120°.

- Basic electrical quantities of the GENSET: the frequency Frequency is measured in Hertz [Hz] and is a basic quantity of alternating currents. For historical reasons, there are two world standards for power system frequency: 50 or 60 Hz. To date, there are still countries which, according to area, operate at different frequencies. The electric frequency generated by a GENSET is directly proportional to engine rpm and the number of poles on the alternator.

Basic electrical quantities of the GENSET: electrical power

A basic quantity when selecting a GENSET is the electric power rating. To understand the concept of power, it can help to think of it as physical labour: power allows me to understand how much work I can do within a determined space of time. The electrical power of a GENSET is intended as the net power available at the power outlet terminal board, minus the power absorbed by the auxiliary systems essential for its own operation (e.g.: cooling fan).

There are 2 types of electrical power:

- Apparent power: measured in VoltAmpere (VA) and is symbolised by the capital letter “S”. It is the theoretical power which can be absorbed by the generator terminals; how much of this will transform into work depends on the efficiency of the load.

- Active power: measured in Watts [W] and is symbolised by the capital letter “P”. It is the power which physically transforms into work. “P” depends on the load and its capacity to transform as much apparent power into active as possible. The ratio between active power and apparent power is defined as a power factor or “cosf“ and the formula which regulates them is P=S*cosf

How can the Active power of a GENSET be declared if the load in unknown?

By agreement, ISO8528 specifies the nameplate of a GENSET refers to cosf=0.8. In reality the cosfi of a load can be variable and also change as a function of the work phase (for example it can be different in an electric motor during the start up phase compared to when it is in full operation); for systems, generally, a low utilities power factor creates drawbacks which affect not only performance, but also the costs of operating the system. In fact, a low cosf results in a decrease in the power available to supply the systems or an over-sizing of systems with the same active power.

POWER RATINGS

The type of use for which a generator set is applicable is determined by the reference power ratings. The rating must be defined on the nameplate affixed to the GENSET. The power ratings are themselves governed by ISO8528-1.

COP: continuous operation power

This is the maximum power a GENSET can supply during continuous service, with a constant load for an unlimited number of operating hours, in the ambient conditions determined by the manufacturer and observing the maintenance intervals established by the manufacturer.

PRP: prime power

This is the power a GENSET can supply during continuous service (unlimited number of hours) with a variable load, in the ambient conditions determined by the manufacturer and observing the maintenance intervals established by the manufacturer. The average power delivered over a 24 hour period must not exceed X% of the PRP power listed on the nameplate, where X is determined by the engine manufacturer. An overload of Y% is permissible at regular intervals. Here as well, the value of Y and the time intervals are determined by the engine manufacturer. X is typically 75% while Y is set at 10%, however these values may lower.

LTP: Limited-time power

This is the maximum power a GENSET can supply for an operating period limited to Z1 h/year in intermittent mode, or Z2 h/year in continuous mode, in the ambient conditions determined by the manufacturer and observing the maintenance intervals established by the manufacturer. The values Z1 and Z2 are set by the engine manufacturer, and an overload is not permitted under any circumstances.

ESP: Emergency Standby Power

This power is similar to the PRP power but referred to a maximum annual operating time of 200 hours.

DCP: Data Center Power

This power rating was recently introduced to regulate a power rating established by engine manufacturers for applications intended for Data Centers, it means DCCs. The DCP defines the maximum power that can be supplied at a continuous or variable load for an unlimited number of hours per year. This power is applicable under the genset manufacturer’s responsibility. He himself, in turn, must ensure that the destination application complies with the standards established by the engine manufacturer for applicability (site quality, quality of the liquids used, auxiliary accessories that must be suitable for the installation site).

ATTENTION: The power rating must be specified before purchasing a GENSET as it also a factor when selecting the engine.

AMBIENT CONDITIONS OF REFERENCE

All of the above-mentioned performance parameters must be declared together with the ambient conditions of reference. ISO8528 gives indications in this instance, as well. Typical reference values are: -temperature 25°C; -altitude 100 m.a.m.s.l.; -relative humidity 30%; -atmospheric pressure 100kPa. In general, the range of ambient conditions in which the machine can operate, without downgrading, must be listed in the machine documentation. Conditions other than those indicated result in performance downgrades. To determine the downgrading of the machine, the performance of the main components in the ambient conditions foreseen by the GENSET manufacturer must be considered: the component most adversely affected is the one which determines the new limit of use. For certain situations, this downgrade can be obtained by means of an analytical table; in other cases, it can be obtained empirically through special testing.