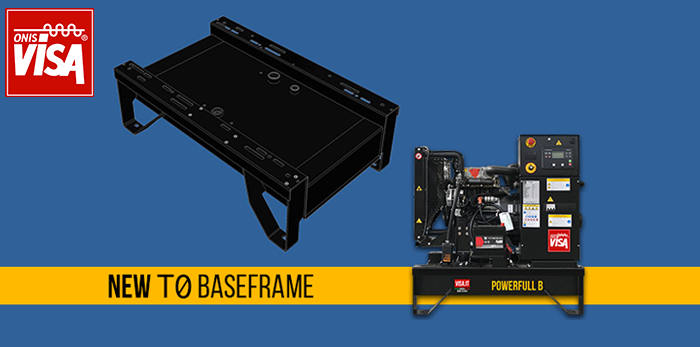

VISA INNOVATION: ALWAYS ON THE FRONT LINE - NEW BASEFRAME

Visa SpA has achieved another goal and completed the project referring to a new version of baseframe, mainly revised and improved to be constantly in line with the company’s growth strategy, working daily to deliver premium products that can totally fulfill the market requirements.Thanks to the constant effort of our engineering department we present the new T0 baseframe.

This product has been designed and manufactured revising the previous version, obtaining a component even more solid and robust to work in the most severe conditions and combining a more compact structure in relation to the T1 version.

Here are the main advantages:

ROBUSTNESS: it combines a robust chassis designed for demanding use with versatility, to be able to house multiple genset models based on the power, and the brand on the engine and alternator. The baseframe acts as fuel tank.

HIGH LEVEL QUALITY: Also the revised version of the baseframe guarantees the same reliability and durability of the previous version. The main feature is a steel sheet metal panel folded lengthwise and is manufactured from thick welded steel. As per all Onis Visa products, also the baseframes are subjected to the strictest tests before and after assembly.

SOLUTIONS: the top part of the tank is shaped as to serve as a retention basin for any small dripping during normal filling and maintenance operations. The baseframe is fitted with supporting feet to keep it raised off the floor and to allow the genset to be handled with a forklift. There are slots on the supporting feet so that the baseframe can be secured to the floor.

PAINTING: each part is painted with thermosetting powder with a specifically selected polyester resin base to make it highly resistant to atmospheric agents; the pigments are distinguished by very high stability against light and heat, protecting the steel from rust, which confers greater durability to the product. The painting process for each part is preceded by a phosphor-degreasing cycle and demineralized water rinse at 170°. After the powder-coated paint is applied, the component is kept in special oven to complete the polymerization process.

EQUIPMENT: the T0 series frames are prepared for the installation of additional accessories to meet all the client’s specific needs: filler cap, electric fuel level gauge, sleeves for the automatic loading system connection, connecting sleeves for the engine power supply circuit, bottom plugs to empty and clean the tank.

COMPETITIVE PRICE: another aspect of the new baseframe is its competitive price. Thanks to the vertical production system and other relevant manufacturing processes, it has been possible to make it more convenient and revised also in terms of price.

By choosing Onis Visa products, the customer knows to be fully and reliably supported through quality and expertise which are among the main aspects our company always focuses on.