General description

The INOX genset range features special canopies and baseframes designed to protect the generating set from atmospheric agents and corrosion, while also ensuring noise reduction and easy access for maintenance. It is ideal for installations in harsh environments or coastal areas.

This option is available in the following ranges: Fox, Galaxy (GV30-GV60-GV100), Galaxy Plus (GV121-GV151-GV201)

Applications

- Port sector

- Hotel/Seafront resorts

- Pharmaceutical and chemical sectors

- Installations in highly corrosive environments

- Industrial plants with high hygiene and health requirements

The importance of the anti-corrosion treatment in the genset sector

In the genset sector, corrosion resistance is a crucial factor, especially for equipment installed in hostile environments such as coastal areas or marine areas with high salinity. The presence of salt in the air significantly accelerates the corrosive processes, undermining the durability and efficiency of metal structures. Offering effective anti-corrosion solutions means ensuring not only the longevity of the machinery, but also safe and reliable operation over time. To address these challenges, Visa offers customized and cutting-edge solutions, designed to meet the specific needs of the customer.

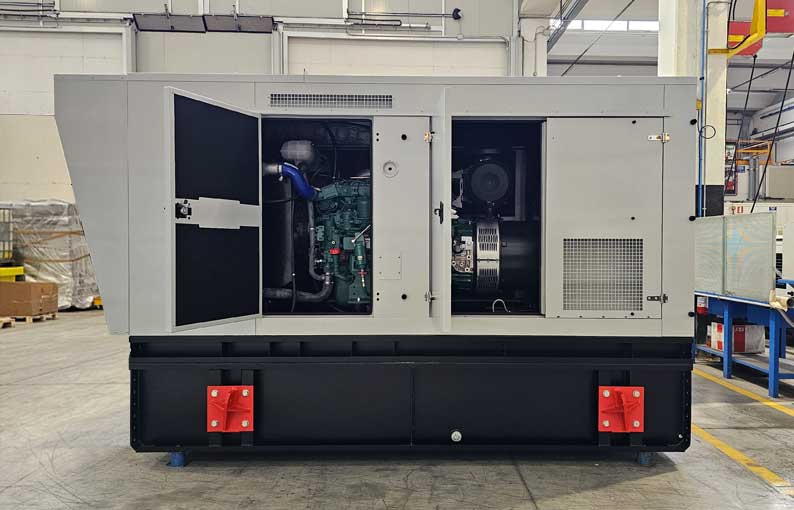

INOX Canopy

It is manufactured in INOX (stainless steel), it represents an advanced protection for the generating set thanks to the high resistance anti-corrosion treatment. This process provides:

- Base Primer: A preliminary application of primer ensures perfect paint adhesion while creating a protective barrier against external elements.

- High-Resistance Painting: This coating is made with thermosetting powders based on polyester resins, specifically selected for their resistance to atmospheric agents, with a minimum thickness of 70 microns. The standard color for the INOX range is gray (RAL 7035).

- INOX components: Structural rivets and hinges are made entirely of stainless steel to ensure optimal resistance to corrosive agents and maximize long-term durability.

- Viewing window (standard): equipped with UV protection, allowing external monitoring of parameters.

This configuration can be customized to meet the specific requirements of the sector or installation site.

Sturdy baseframe and advanced treatments

The genset baseframe is made of steel and undergoes a dual painting process (cataphoresis + powder coating) followed by baking. This process ensures uniform and long-lasting protection, even in the harshest environmental conditions.

- Cataphoresis Coating Process: the entire baseframe is immersed in a paint bath and fixed using an electrophoretic process, followed by oven baking to allow the paint to polymerize.

- Second Coating Cycle: a second layer of thermosetting powder coating, based on polyester resins, is applied and finalized with an additional baking cycle for the baseframe

The dual coating process provides superior corrosion protection compared to single powder coating. It also grants high mechanical and chemical resistance to the baseframe, ensuring operational effectiveness while minimizing long-term maintenance costs.