GENERATORS MANUFACTURING

Visa SpA is a leading Italian company that has been successfully present on the market since 1960, planning and manufacturing high-tech generating sets and power stations. "ONIS VISA" gensets and power stations, ranging from 9 to 3,000 kVA, are completely manufactured in Italy and offer the best in terms of quality and technology. The company has total control over every phase of production, from the punching and cutting of metal sheets, to bending and automatic painting. Even the assembly phases and bench tests, which are carried out on every finished item, are managed internally, as is packaging before final shipment.

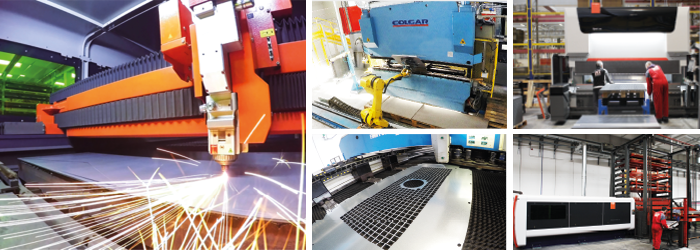

BASEFRAMES AND CANOPIES - technological area

The superior quality range of baseframes and canopies are manufactured by professionals in compliance with international quality standards. The whole range is manufactured using the latest technology, innovative machines and the finest raw materials. Moreover, all items are tested according to the strictest parameters to ensure quality and durability. Thanks to laser cutting technology, complex shapes can be cut without the need for tooling at the same rate or faster than other cutting methods. FROM STEEL SHEET TO FINAL PRODUCT: 100% MADE IN ITALY

BASEFRAMES AND CANOPIES - welding area

Canopies, baseframes and fueltanks are manufactured using state of the art robot welding systems, allowing for precise and accurate work even for large length welds and obtaining certifiable sealed products. Thanks to this modern manufacturing equipment Visa SpA has succeeded in increasing efficiency, production speed and the quality of the welding itself, as well as reducing the margin of error and meeting any customer’s requirements. There are also 15 welding work-stations, used by particularly experienced professionals, for the finishing and processing of small customized components. Quality hand-crafted work, typical of Made in Italy products.

INDUSTRIAL PAINTING AREA - Powder Coatings

Each part of every Onis Visa product is painted with thermosetting powders that are specifically selected for their heat-resistance and elevated resistance to atmospheric agents. The painting process is preceded by a phospho-degreasing cycle with a demineralized water rinse and a drying phase. After the power-coated paint is applied, the component is kept in the oven until polymerization is complete.

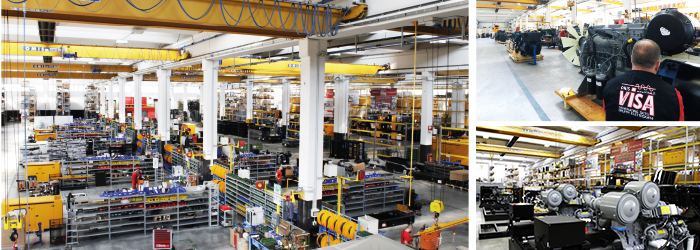

GENERATING SETS - ASSEMBLY AREA

1700 sqm of the Power Division are entirely dedicated to generating set assembly. LEAN METHODOLOGY is at the foundation of the company philosophy; the production cycle system is constantly implemented to optimize the manufacturing phases and minimize delivery times, always maintaining a high level of quality. Work stations are organized according to the gensets’ power size and the whole operating process is obtained to avoid any possible waste and so that production can be managed according to the “Just-In-Time” process. In fact, all products are highly customized according to the customers’ specifications and the specific nature of their reference markets.

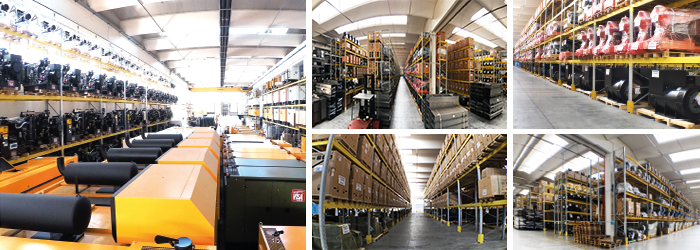

WAREHOUSES - JUST IN TIME philosophy

In order to allow for Just-In-Time production, more than 1000 engines and alternators are constantly available in stock, and a large finished goods warehouse stores genset units of different power sizes and versions, so that they are always available for immediate delivery.